With our country’s familiarity with artificial sand technology, sand making machine technology has developed from PCL impact crusher to the fifth and sixth generation VSI sand making machine. Compared with the traditional PCL sand making machine, the new VSI sand making machine has been improved in what aspects and how is the effect? Take a look!

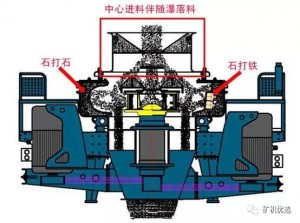

PCL as the center feed, VSI has a complete center feed and center feed with ring waterfall feed two, VSI5X (fifth generation sand making machine) is the bulk tray device, can quickly realize the center feed and waterfall feed conversion, reduce the shutdown adjustment time, improve efficiency. VSI4X (the fourth generation of sand making machine) adopts the bulk cone device, the bulk cone can be removed to achieve complete center feeding.

The single feeding mode of PCL sand making machine determines that the life of its wearing parts is short, while VSI is different:

1) With the combination of the two feeding methods, the wearing parts have longer working life and higher economic benefits;

2) The optimized arrangement design of wear-resistant materials can increase the service life by more than 40% and reduce the cost by more than 40%;

3) In the production process, stone can form a protective bottom, fuselage wear is small, durable.

PCL itself has no open cover maintenance mechanism, maintenance down time-consuming and laborious, and VSI is equipped with automatic maintenance open cover mechanism, as long as the open cover can be repaired the body, saving time and labor, maintenance cost is greatly reduced.

Both VSI4X and VSI5X sand making machines adopt hydraulic device to automatically open the cover, which is convenient and quick to remove the top cover and reduce the manual labor intensity. Even if only one person can easily replace the rotor and its accessories, convenient maintenance and improve the use efficiency.

PCL uses dry oil lubrication system, poor heat dissipation function, greatly loss of spindle bearing service life, improve the maintenance cost. The VSI sand making machine adopts light oil lubrication system, which can effectively dissipate heat during the operation of the spindle bearing to ensure that the temperature rise is within 25℃ and prolong the service life of the bearing. The light oil system can effectively lubricate and reduce bearing friction in the working process, improve the bearing speed, thus greatly improving the working efficiency.

PCL uses the profile welding process, the production of material selection is simple, the structural strength is poor, VSI uses the steel plate bending hot rivet process, the body appearance has more environmental protection concept, enhance the structural strength and toughness of the equipment, ensure the smooth operation of the equipment, so that the quality rises to a new level.

The PCL sand making machine uses a shallow cavity type rotor, which makes the processing capacity of the equipment greatly reduced when producing materials, which leads to the low production capacity of the equipment. Relatively speaking, the deep cavity rotor used by VSI sand making machine can greatly improve the processing capacity of the equipment for materials.

VSI5X has optimized the deep cavity rotor design, which increases the material flow by about 30%. VSI6X adopts four-channel rotor, and the crushing efficiency is increased by 10%~20%.

Post time: May-27-2023