1. Basic principles and guiding ideology of design:

(1) Implement the guiding ideology of “people-oriented”;

(2) Implement the safety production policy of “safety first, prevention first”;

(3) Select equipment with low energy consumption, high efficiency, safety and reliability, and easy operation and maintenance;

(4) Choose reasonable mining techniques and development and transportation plans, striving for technical reliability and economic rationality, while avoiding environmental hazards while developing and utilizing mineral resources.

2. The main content of the design includes production systems and auxiliary systems, which are mainly divided into the following three parts:

(1) Mining:

Determination of open-pit mining boundary;

Determination of development methods and mining methods;

Selection of production process;

Verification and selection of production equipment capacity (excluding ore processing and external transportation equipment and facilities).

(2) Auxiliary system:

Mining area general plan transportation;

Mining power supply, machine maintenance, water supply and drainage, heating;

Construction of mining departments and production and living facilities;

Safety and industrial hygiene;

Environmental protection in mining areas.

(3) Estimated investment and economic benefits of the enterprise.

Based on existing information and the current mining situation, after consultation with the owner, this design only provides a complete design for the mining project. Auxiliary facilities (such as mechanical maintenance, automotive maintenance, electrical maintenance, water supply, power supply, external transportation and communication at the mining site) and welfare facilities are only preliminarily estimated. The owner conducts relevant technical modifications based on the original facilities compared to the design to meet the design requirements. This design only includes the estimated budget in the total investment for financial evaluation and economic analysis.

3. Preventive measures in design:

Treatment methods for goaf

For limestone mines, after the pit is closed, tree planting or re cultivation can be carried out after covering with soil.

Measures to ensure the final slope stability of open-pit mines and prevent slope collapse

(1) Conduct mining according to relevant design parameters and set up safety platforms in a timely manner.

(2) For blasting near the final border state, controlled blasting is used to maintain the integrity of the rock mass and the stability of the border state.

(3) Regularly inspect the stability of slopes and border states, and promptly clean loose floating stones. Cleaners should wear safety helmets, fasten safety belts or safety ropes.

(4) Construct intercepting ditches at suitable locations outside the mining area and temporary drainage ditches inside the mining area to timely remove accumulated water in the mining area, in order to avoid slope collapse caused by water immersion.

(5) For weak rock slope, such as soil slope, weathered zone slope, fractured zone slope, and weak interlayer slope, reinforcement methods such as anchor spraying, mortar masonry, and shotcrete are adopted.

Prevention of electrical hazards and lightning protection measures

There are fewer and more concentrated electrical equipment in mines. To prevent electric shock accidents, measures should be taken as follows:

(1) Install safety protection devices, metal fences at windows, and safety warning signs in the generator room;

(2) Add one mining charging emergency light and a 1211 fire extinguisher in the generator room;

(3) Open the door of the generator room outward to facilitate escape;

(4) Replace some of the lines with aging insulation, rectify non-standard lines, and organize the power lines in the generator room to ensure orderly arrangement; The lines passing through the measuring room need to be separated and cannot be tied together, and protected with insulating sleeves;

(5) Timely repair and replace defective electrical appliances on the distribution panel;

(6) Equip equipment prone to mechanical accidents with emergency shutdown devices. When cleaning and wiping equipment, it is strictly prohibited to rinse with water or wipe electrical equipment with damp cloth to prevent short circuits and electric shock;

(7) Safety measures for electrical maintenance:

Implement a work ticket system, work permit system, work supervision system, work interruption, transfer, and termination system for the maintenance of electrical equipment.

Low voltage live working should be supervised by dedicated personnel, using tools with insulated handles, standing on dry insulating materials, wearing gloves and safety helmets, and wearing long sleeved clothing. It is strictly prohibited to use tools such as files, metal rulers, and brushes or dusters with metal objects. For work on low-voltage distribution boxes and power mains, work tickets should be filled out. When working on low-voltage motors and lighting circuits, verbal communication can be used. The above work shall be carried out by at least two people.

Safety measures for low-voltage circuit power outage:

(1) Disconnect the power supply of all aspects of the maintenance equipment, remove the fuse (fuse), and hang a sign on the switch operation handle saying “No Switching On, Someone is Working!”.

(2) Before working, it is necessary to check the electricity.

(3) Take other safety measures as needed.

After replacing the fuse after a power outage, gloves and goggles should be worn when resuming operation.

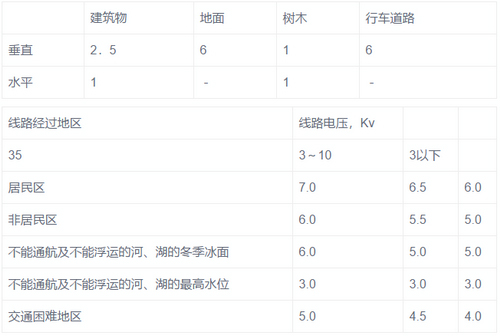

Requirements for safe distance: The minimum distance between low-voltage overhead lines and buildings.

The overhead power line protection zone is the area formed by the sum of the maximum calculated horizontal distance of the wire edge after wind deviation and the horizontal safe distance from the building after wind deviation, within two parallel lines. 1-10kv is 1.5m. The width of the underground power cable protection zone is the area within two parallel lines formed by 0.75m on both sides of the ground stakes of the underground power cable line. The high-voltage transmission line should be higher than the highest part of various mechanical equipment by more than 2m, and the low-voltage transmission line should be higher than the highest part of various mechanical equipment by more than 0.5m. The vertical distance between overhead conductors and buildings: under the maximum calculated sag, for 3-10kV lines, it should not be less than 3.0m; And meet the requirements of the “Safety Regulations for Metal and Non metallic Mines” (GB16423-2006).

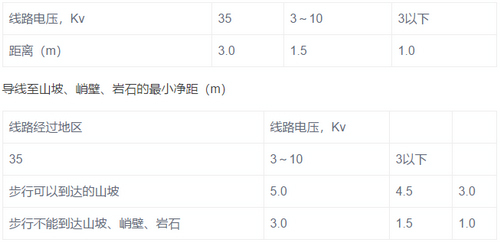

Minimum distance from wire to ground or water surface (m)

Minimum distance from edge wire to building

The lightning protection facilities shall be designed strictly in accordance with the relevant provisions of the “Code for Design of Lightning Protection of Buildings”.

Mine buildings and structures shall be considered as Class III lightning protection. All buildings and structures with a height of 15m and above shall be provided with lightning protection net and belt, and some of them shall be provided with lightning rod for protection.

Mine generator rooms, overhead lines, material warehouses, and oil storage tanks are the main lightning protection objects, and lightning protection facilities should be installed.

Preventive measures for mechanical hazards

Mechanical injury mainly refers to injuries caused by direct contact between moving (stationary) parts, tools, and machined parts of mechanical equipment and the human body, such as pinching, collision, shearing, entanglement, twisting, grinding, cutting, stabbing, etc. The exposed transmission parts (such as flywheel, transmission belt, etc.) and reciprocating motion parts of rotating machinery such as air compressors, rock drills, loaders, etc. in this mine may cause mechanical damage to the human body. At the same time, mechanical injury is also one of the most common injuries in mining production, and equipment that can easily cause mechanical injury includes drilling, compressed air, and shipping equipment. The main preventive measures include:

(1) Mechanical equipment operators must learn equipment structure, operating principles, operating methods, and other knowledge, and understand the prevention methods for various accidents during equipment operation. Special equipment operators must pass the assessment and operate with certificates. Non operators are strictly prohibited from starting and operating the equipment to avoid accidents such as personal injury or damage.

(2) Mechanical equipment should be installed in accordance with the equipment manual and relevant regulations, and the protective covers of the operating components of the equipment must be complete and intact.

(3) People should avoid the range of motion of moving equipment (such as cars, loaders, etc.) and install protective devices to prevent moving parts from falling off.

(4) The measures for controlling mechanical injury mainly include setting up protective barriers, protective covers, protective nets or other protective facilities for various rotating machinery, in order to isolate the dangerous parts of the human body and equipment. Mechanical protective devices should comply with the “Safety Requirements for Protective Covers of Mechanical Equipment” (GB8196-87); Safety Technical Conditions for Fixed Industrial Protective Railings (GB4053.3-93).

Waterproof and drainage measures

The mine is a hillside open-pit mine, with a minimum mining elevation of 1210m higher than the local minimum erosion benchmark. Groundwater has little impact on mining, and the water filling in the mining site is mainly caused by atmospheric rainfall. Therefore, the focus of mine drainage and prevention work is to prevent the impact of atmospheric rainfall surface runoff on the mine.

The main waterproof and drainage measures of the mine include: setting up interception and drainage ditches outside the mining area, and setting a slope of 3-5 ‰ on the working platform to facilitate drainage; Install longitudinal drainage ditches and horizontal culverts for drainage on roads.

Dustproof

Dust is one of the main occupational hazards in mining production. In order to effectively control the escape of dust and reduce the impact of dust on workers on the job, this project implements a policy of prevention first, and tries to minimize dust emission in the process flow:

(1) The drilling rig shall be equipped with a down-the-hole drill with a dust catching device, and dust prevention measures such as ventilation and water spraying shall be strengthened during drilling;

(2) Frequent watering should be carried out on highways to reduce dust emissions during vehicle transportation;

(3) After blasting, personnel are not allowed to enter the blasting area immediately. Only after the dust naturally dissipates can they enter the site to reduce the impact of dust;

(4) Regularly conduct dust concentration testing in the workplace air to ensure that the dust concentration in the workplace air meets the requirements of the Occupational Exposure Limits for Hazardous Factors in the Workplace;

(5) Provide personal protective equipment for mining operators and conduct regular health checks for all personnel.

Noise control measures

In order to control noise pollution, low-noise equipment should be selected as much as possible in the design; Install silencers on high noise pneumatic equipment such as air compressors and drilling rigs; In high noise places, workers are required to equip personal protective equipment such as sound insulation earmuffs to reduce the impact of noise on workers.

Blasting safety measures

(1) When carrying out blasting operations, it is necessary to strictly follow the “Blasting Safety Regulations”. Depending on the blasting method, scale, and terrain characteristics, according to the blasting safety regulations, the boundary of the blasting danger zone must be delineated according to the requirements of the blasting earthquake safety distance, blasting shock wave safety distance, and individual flying objects safety distance. Safety warning signs must be set up, and warning work must be done to ensure the safety of personnel and property.

(2) Each blasting must have an approved blasting design. After blasting, safety personnel must carefully inspect the safety situation of the working face and confirm the safety of the blasting site before resuming operations.

(3) Personnel engaged in blasting operations must have received training in blasting technology, be familiar with the performance, operation methods, and safety regulations of blasting equipment, and hold a certificate to work.

(4) Blasting operations are strictly prohibited in dusk, heavy fog, and thunderstorms.

(5) The blasting near the final border state is controlled to maintain the integrity of the rock mass and the stability of the border state.

Post time: Apr-14-2023