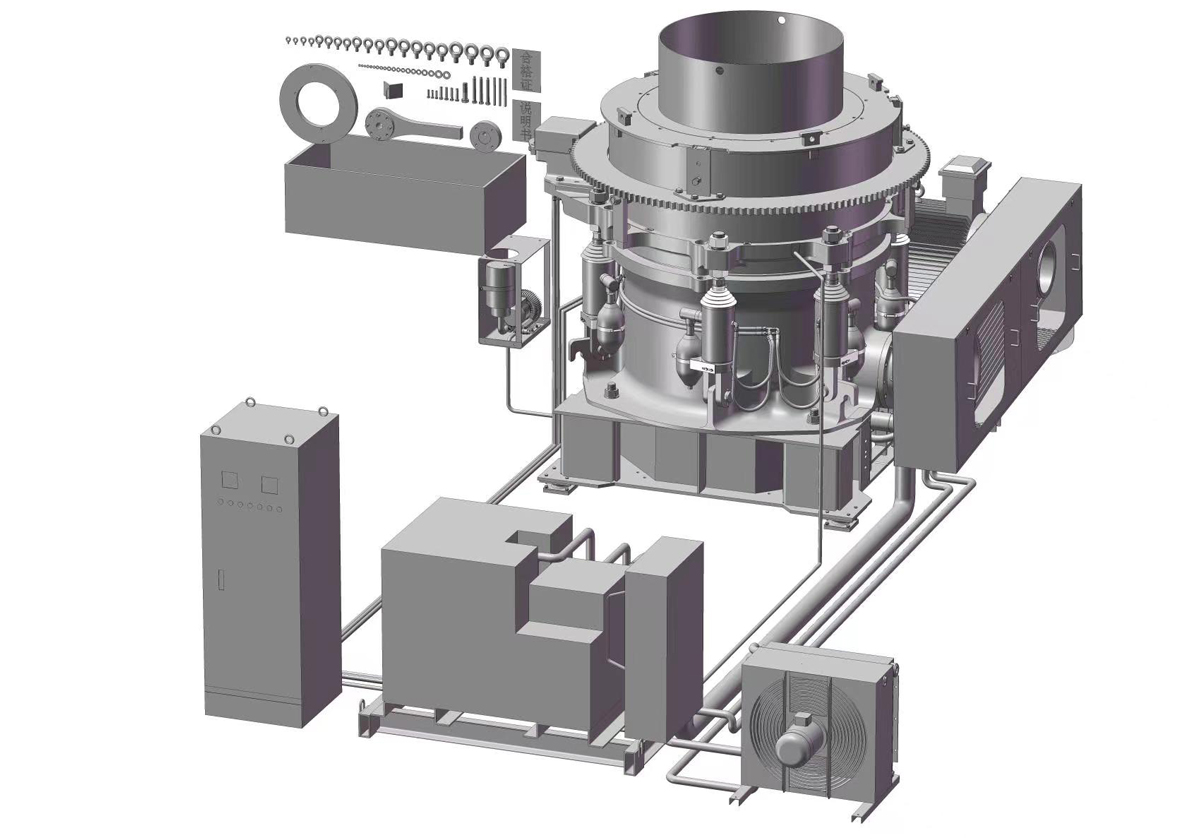

Multi Cylinder Cone Crusher Easy to Operate

Product Description

Hydraulic control to adjust the discharge port, easy to operate , a Variety of cavity shape adjustment accurate, saving time and effort.

Hydraulic control “over iron” protection, cavity cleaning reduces downtime we have made great efforts to improve the mechanical properties of cone crusher parts, such as frame, main shaft, bevel gears, eccentric, etc. Our cone crushers offer high productivity and low operating and wear costs and long service life.

Application

Sand and stone plant, concrete mixing plant, dry mortar, power plant desulfurization, quartz sand, etc., Iron, gold, copper and other metallic mineral materials; Pebble, granite, basalt, limestone, quartzite, diabase and other non-metallic materials.

Feature

Grain size uniform

The principle of crushing is laminating, it is not only effectively reduce wear, prolong the service life of wearing parts, but also make the finished cube account for a higher, fewer needle and flake products, more uniform grain size, and meet the needs of high quality. With unique working principle and optimized structure, it has stronger carrying capacity, larger installed power and higher production capacity.

Hydraulic protection, oil lubrication

Hydraulic control discharge port, overload protection and cavity cleaning action, make the equipment running smoothly and safely, reduce the downtime and maintenance time, improve the crushing efficiency. Unique thin oil lubrication system, greatly improve the service life of equipment.

Increased degree of Automation

Advanced PLC electrical system be used, it can continuously monitor the state of operation, simple operation, safe and reliable; the single operation system can also be integrated into the production line control system to complete the linkage control system.

Multi-purpose a machine convenient maintenance

Only the replacement of liner and other related parts can make the cavity shape conversion, to meet the requirements of medium and fine crushing. Reasonable structure, reliable operation, low operation cast, high quality of finished products.

Product Parameter

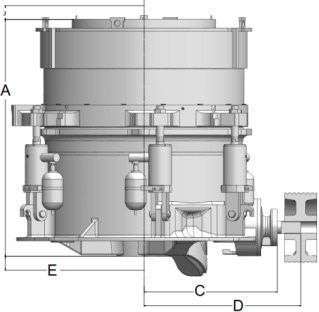

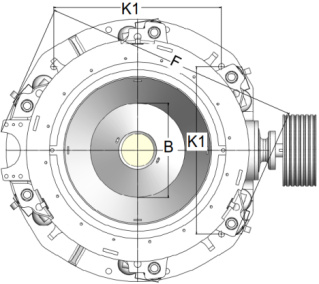

QHP500 Technical Parameter

|

A |

2290 |

|

|

B |

1535 |

|

|

C |

1760 |

|

|

D |

2650 |

|

|

E |

425 |

|

|

F |

2730 |

|

|

J |

125 |

|

|

K1 |

1764 |

|

QHP500 Passage Range |

|||||||||||

|

CSS mm |

10mm |

13mm |

16mm |

19mm |

22mm |

25mm |

32mm |

38mm |

45mm |

51mm |

65mm |

|

Passage t/h |

175-220 |

230-290 |

280-350 |

320-400 |

345-430 |

365-455 |

405-535 |

445-605 |

510-700 |

580-790 |

650-950 |

|

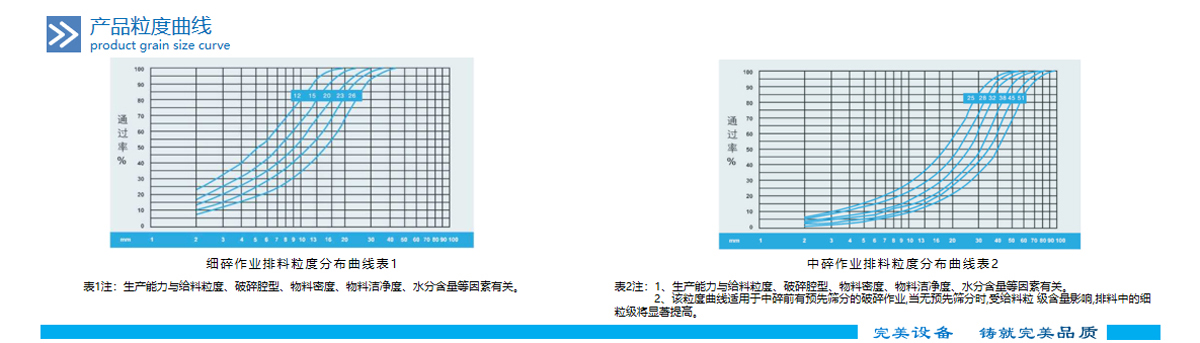

Products scale curve |

|||||||||

|

Standard cavity operation discharge distribution curve |

Short cavity operation discharge distribution curve |

||||||||

|

Cavity type |

CX |

C |

M |

MF |

Cavity type |

SC |

SM |

SF |

SFX |

|

Discharge open range (mm) |

30-65 |

25-65 |

20-65 |

16-65 |

Discharge open range (mm) |

13-65 |

10-65 |

8-65 |

6-65 |

|

CSS (mm) |

355 |

286 |

204 |

133 |

CSS (mm) |

95 |

57 |

52 |

53 |

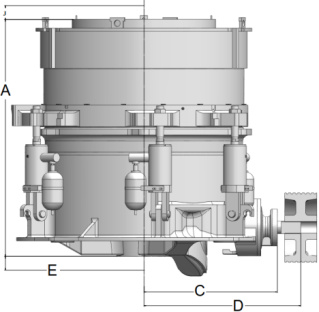

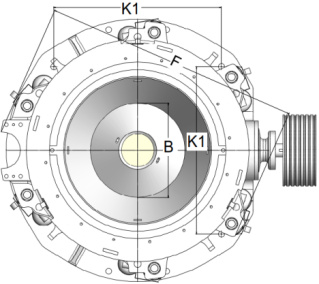

QHP400 Technical Parameter

|

A |

2057 |

|

|

B |

1308 |

|

|

C |

1645 |

|

|

D |

2475 |

|

|

E |

240 |

|

|

F |

2370 |

|

|

J |

152 |

|

|

K1 |

1660 |

|

QHP400 Passage Range |

|

||||||||||

|

CSS mm |

10mm |

13mm |

16mm |

19mm |

22mm |

25mm |

32mm |

38mm |

45mm |

51mm |

65mm |

|

Passage t/h |

140-175 |

185-230 |

225-280 |

255-320 |

275-345 |

295-370 |

325-430 |

360-490 |

410-560 |

465-630 |

|

|

Products scale curve |

|||||||||

|

Standard cavity operation discharge distribution curve |

Short cavity operation discharge distribution curve |

||||||||

|

Cavity type |

CX |

C |

M |

MF |

Cavity type |

SC |

SM |

SF |

SFX |

|

Discharge open range (mm) |

30-65 |

25-65 |

20-65 |

14-65 |

Discharge open range (mm) |

10-65 |

8-65 |

6-65 |

6-65 |

|

CSS (mm) |

299 |

252 |

198 |

111 |

CSS (mm) |

92 |

52 |

51 |

52 |

QHP300 Technical Parameter

|

A |

1866 |

|

|

B |

1078 |

|

|

C |

1347 |

|

|

D |

2023 |

|

|

E |

328 |

|

|

F |

2207 |

|

|

J |

87 |

|

|

K1 |

660 |

|

QHP300 Passage Range |

|

||||||||||

|

CSS mm |

10mm |

13mm |

16mm |

19mm |

22mm |

25mm |

32mm |

38mm |

45mm |

51mm |

65mm |

|

Passage t/h |

115-140 |

150-185 |

180-220 |

200-240 |

220-260 |

230-280 |

250-320 |

300-380 |

350-440 |

||

|

Products scale curve |

|||||||||

|

Standard cavity operation discharge distribution curve |

Short cavity operation discharge distribution curve |

||||||||

|

Cavity type |

CX |

C |

M |

MF |

Cavity type |

SC |

SM |

SF |

SFX |

|

Discharge open range (mm) |

25-65 |

19-65 |

17-65 |

13-65 |

Discharge open range (mm) |

10-65 |

8-65 |

6-65 |

6-65 |

|

CSS (mm) |

233 |

211 |

150 |

107 |

CSS (mm) |

77 |

53 |

22 |

25 |

According to technical changes and updates, the technical parameters of the equipment are adjusted at any time. You can directly contact us to obtain the latest technical parameters.